ABSORBING IMPACT: INSIDE THE HEAD OF A WOODPECKER

by Associate Professor Dr Ahmad Kueh Beng Hong

Faculty of Engineering

Faculty of Engineering

Scientists at Universiti Malaysia Sarawak (UNIMAS) are using computational modelling to optimise the ability of composite sandwich beams to absorb strong impacts. They applied their approach to a beam design inspired by the woodpecker's head, changing aspects of the structure to find the optimal solution. The findings were published in the journal Composite Structures.

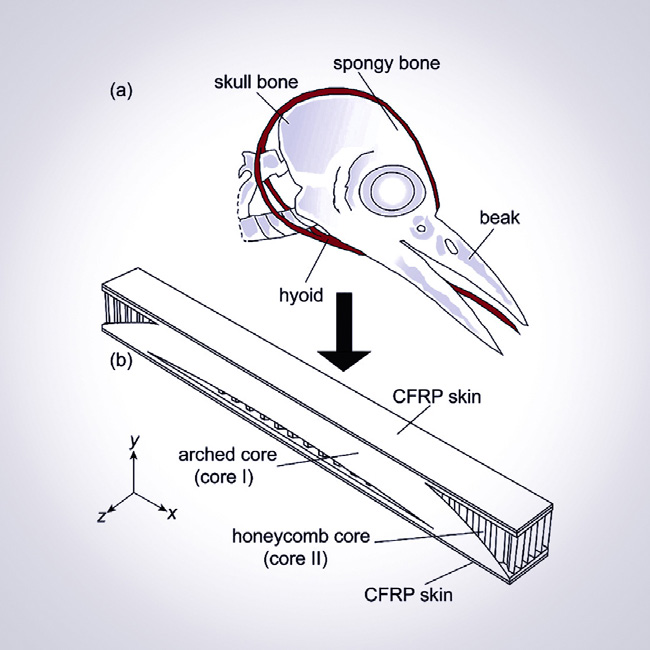

"Sandwich beams are used in construction, and the aviation and automotive industries due to their superiority over many conventional structures in terms of their enhanced energy absorption, light, weight, stability, and ability to protect occupants during a crash," says UNIMAS structural engineering lecturer, Associate Professor Dr Ahmad. Such beams are made of an upper and lower skin sandwiching a light-weight inner core. Much research has been done on a variety of sandwich beam designs, involving different types and shapes of inner cores. Core designs have been geometrically inspired, employed the concepts of Japanese folding art, or have even been driven by natural designs found in animal and plant kingdoms.

"Sandwich beams are used in construction, and the aviation and automotive industries due to their superiority over many conventional structures in terms of their enhanced energy absorption, light, weight, stability, and ability to protect occupants during a crash," says UNIMAS structural engineering lecturer, Associate Professor Dr Ahmad. Such beams are made of an upper and lower skin sandwiching a light-weight inner core. Much research has been done on a variety of sandwich beam designs, involving different types and shapes of inner cores. Core designs have been geometrically inspired, employed the concepts of Japanese folding art, or have even been driven by natural designs found in animal and plant kingdoms.

Inspired by the woodpecker's ability to strike trees with its beak rapidly and repeatedly without injury, engineers in Malaysia have used computer simulations to find ways to improve the design of composite beams used in impact-prone structures.

Among these, a design inspired by the woodpecker's head has shown promise. However, there is still much room for improvement. Assoc. Prof. Dr Ahmad and his colleagues used an engineering software tool, called ABAQUS, to simulate what might happen to woodpecker-inspired sandwich beams upon impact.

Among these, a design inspired by the woodpecker's head has shown promise. However, there is still much room for improvement. Assoc. Prof. Dr Ahmad and his colleagues used an engineering software tool, called ABAQUS, to simulate what might happen to woodpecker-inspired sandwich beams upon impact.

The beam's design is inspired by the ability of the woodpecker's head to protect its brain from injury.

They assumed a beam made with outer skins of polymer laminate reinforced with carbon fibre. The inner core was composed of two parts: a surrounding arch made of hot glue and an aluminium-based honeycomb. Experimentally-known details of the various materials, such as density, stiffness and tensile strength, were input into the software program. The researchers then tested how impact affected the beam when the hot glue arch was thinner or thicker and the width of the arch's legs, called leg span, changed.

The simulations showed that a thin arch with a short leg span resisted impact best. The beam models with the thickest arches showed the highers contact force, damage area and energy absorption. Thinner arches were maximally stressed, but performed better due to their ability to withstand repeated blows without damage.

The team recommends further research to explore the use of stiffer and less dense materials.

The simulations showed that a thin arch with a short leg span resisted impact best. The beam models with the thickest arches showed the highers contact force, damage area and energy absorption. Thinner arches were maximally stressed, but performed better due to their ability to withstand repeated blows without damage.

The team recommends further research to explore the use of stiffer and less dense materials.